SUSTAINABILITY AND DESIGN

IT ALL STARTS AT THE DRAWING BOARD (DESIGN PHASE)

When designing a product, there are three crucial criteria: the product should contribute to less sedentary behaviour/greater mobility, last as long as possible, and be adaptable according to needs. For example, this means that a student using our height-adjustable table can switch between different working positions, that the table’s components can be replaced, that it is made from durable and environmentally smart materials, and that it can be used by people of all ages. We also strive for a design that follows nature’s forms and stimulates inherent movement patterns.

MATERIAL SELECTION WITH ENVIRONMENTAL CONSIDERATIONS (MATERIAL SELECTION/SOURCING PHASE)

As far as possible, we choose environmentally friendly materials (wood over plastic, etc.) that can be sourced in Scandinavia and that meet limit levels for chemical content. Many of our textiles are environmentally certified (e.g., OEKO-TEX). We use recycled plastic whenever possible, and for some products we offer a “best environmental option”, like our PVC-free anti-fatigue mat, which is made of cork. In the long run, our ambition is for the “alternative” to become standard.

FAIR FOR THE MANUFACTURER (MANUFACTURING PHASE)

When we choose our manufacturers, environmental considerations and proximity are crucial. The majority of them base their production in Scandinavia, where the requirements for good working conditions are relatively strict. Manufacturing close to the end customer also means fewer shipments.

MINIMAL PACKAGING AND SMART LOGISTICS (DISTRIBUTION PHASE)

We mainly use 100% recycled Swedish paper and avoid unnecessary printing and paint. To minimise the number of shipments to our customers, we collect all the products from one supplier and optimise space when shipping. Everyone wins.

GOOD FOR THE BODY, DURABLE, ADAPTABLE (USE PHASE)

This bears repeating. All our products should contribute to less sedentary behaviour and/or encourage the user to move. They should not break in the first place, and parts should be replaceable in the event of wear and tear. And if needs change, our products can be adapted to new uses and users.

PAVING THE WAY FOR A SECOND LIFE (RECYCLING PHASE)

By creating flexible products, we aim to encourage their reuse in a second life. For example, minimising chemical content and using natural materials makes it easier to recycle our products. Our goal and ambition is to develop a service where we re-paint, re-sell, rent, recycle, etc.

OVERALL STANDARDS AND PROCEDURES:

To ensure our customers can feel safe, we use available (voluntary) industry standards. For example, our tables are “Möbelfackta-labelled”, which means they meet Möbelfakta’s quality, environmental, and social responsibility requirements.

For our entrance solutions, we have products that have been assessed by both SundaHus and Byggvarubedömningen.

|

|

|

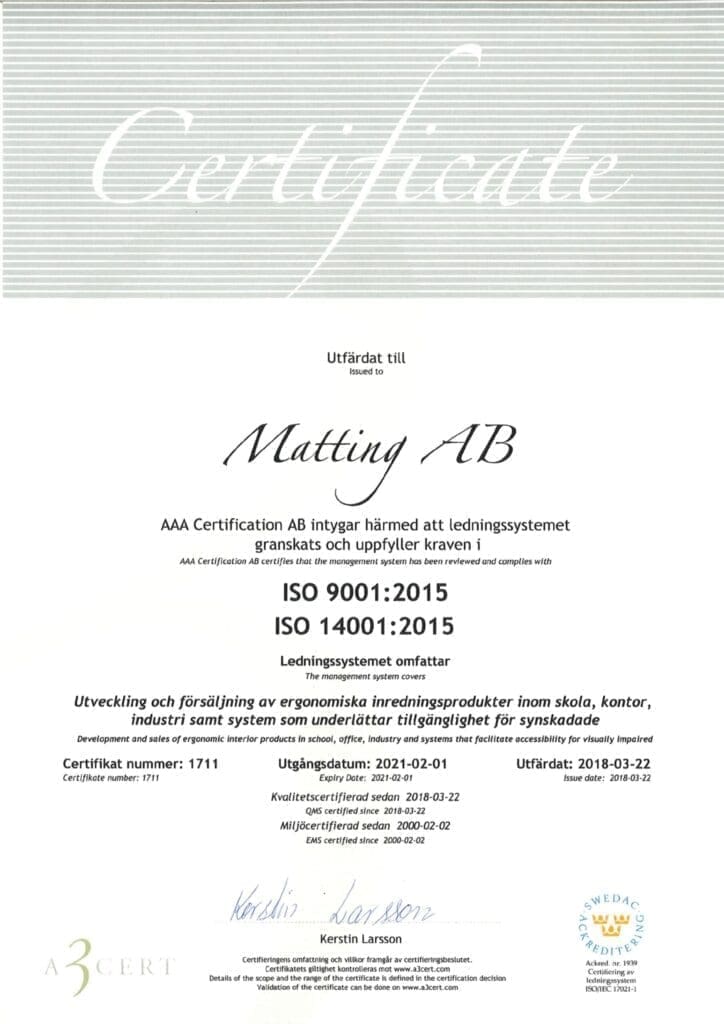

Matting AB has a certified environmental management system according to ISO 14001:2015 and a certified quality management system according to ISO 9001:2015. Among other things, this means that we map our company’s environmental impact and subsequently work with areas where such impact can be reduced.